材料等级Material Grade:1700(MS17型)1800(MS18型)

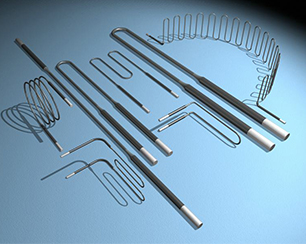

型号Model:I型等直径型硅钼棒

体积密度Volume density:5.5~5.6kg/cm3

抗折强度Bend strength:15~25kg/cm2

维氏硬度(HV)570kg/mm2:(HV)570kg/mm2

气孔率Porosity rate:7.4%

吸水率Water absortion:1.2%

热伸长率Hot extensiblity:4%

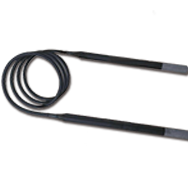

二硅化钼电热元件(硅钼棒)

Mosi2Heating Elements

二硅化钼电热元件是一种以硅化钼为基础的电阻发热元件,其在氧化气氛下加热到高温,表面生成一层致密的石英玻璃膜,保护其不再氧化。因此,其具有独特的高温抗氧化性。在氧化气氛下,其最高温度可达1800C,其适用温度500-1700℃,可以用作陶瓷、磁性材料、玻璃、冶金、耐火材料等工业高温炉的加热元件。

二硅化钼电热元件的机械性质和其它陶瓷制品样,在常温下属于脆性材料容易断裂,这给运输和安装带来了一定的困难,但只要安装合理和使用得当是可以避免的。

Mosi2 , heating element is a kind of resistance heating element basically made of high pure Molybdenum Disilicide. In oxidizing atmosphere,a layer of compact quartz protective film is formed on the surface of Mosi2, element owing to the hightemperature combustion, which prevent Mosi2, from continuously oxidizing. In oxidizing atmosphere, its Max temperature can reach 1800℃, and its applicable temperature is500-1700℃. It can be widely used in such applications as sintering and heat treatment of ceramics, magnet, glass, metallurgy, refactory, etc. The commercial name of our MoSi2, heating elements is Yandi Super Heating Elements.

Having the same mechanical character as other ceramic products, MoSi2, heating elements are brittle materials so that they are easy to rupture at the noumal temperature at the normal temperature, which brings some difficulties to transport and install, but it may be avoided if they were installed and used correctly.

二硅化钼电热元件的标志法Dimension marks of elements

硅钼棒在各个领域,所使用尺寸和形状均根据实际情况定制。您在定制时建议使用以下标志法:

二硅化钼电热元件的标志法

材料等级:1700(MS17型号),1800(MS18型号)

直径:D1/D2,mm/mm

热端长度:Le,mm

冷端长度:Lu,mm

间距:A,mm

例如:

U型,材料等级1800,D1=3mm,D2=6mm,Le=140mm,Lu=125mm,A=25mm 表示为MS18,U型,3/6×140×125×25

W型,材料等级1700,D1=6mm,D2=12mm,Le=300mm,Lu=250mm,A=50mm 表示为MS17,W型,6/12×300×250×50

Material Grade:1700(MS17Model),1800(MS18Model)

Diameter:D1/D2,mm/mm

Hot zone length:Le,mm

Cold end length:Lu,mm

Shank Spacing:A,mm

Examples:

UShape,Material Grade 1800,D1=3mm,D2=6mm,Le=140mm,Lu=125mm,A=25mm Specify as:Yandi Super MS18,UShape,3/6×140×125×25

WShape,Material Grade 1700,D1=6mm,D2=12mm,Le=300mm,Lu=250mm,A=50mm Specify as:Yandi Super MS17,WShape,6/12×300×250×50

www.yandigaowen.com

二硅化钼电热元件的理化性质 Physical and chemical properties of elements

1、物理性质Physical properties

2、化学性质Chemical properties

高温抗氧化性:高温氧化气氛下,元件的表面生成一层致密的石英(SiO2)保护层以防止MoSi2继续氧化。当元件温度大于1700℃,熔点为1710℃的SiO2保护层熔融,由于表面的张力的作用,SiO2熔聚成滴,而失去保护作用。元件在氧化气氛下,再继续使用时,SiO2保护层重新生成。

必须指出的是元件不宜在400-700℃范围内长时间使用。否则元件会因低温的强烈氧化作用而粉化。

Oxygen-resistance under high temperature:in oxidizing atmosphere,a layer of compact quartz(SiO2)protective film is formed on the surface of element owing to the high-temperature combustion,which prevent MoSi2,form continuously oxidezing.When the element temperature is higherthan 1700℃,the SiO2 protective film will be fused because its fusing point is1710℃ and the SiO2 is fused into molten drops owing to the action of its surface extension, which cause losing its protective ability. In the oxidizing atmosphere, when the element is continuously used, the protective film forms again.

It should be pointed out that element cannot be used for rather long time in 400-700℃, otherwise, it will be powdered owing to the strong oxidizing action in lov temperature.

3、不同气氛对元件温度的影响The Max temperature of elements in different atmospheres

二硅化钼电热元件的电气性质Electric properties of elements

1.电阻特性Resistance properties

1700等级和1800等级元件的电阻-温度曲线

二硅化钼电热元件的电阻率随着温度的升高而迅速增加。在正常操作情况下,元件电阻一般不随使用时间的长短而变化。因此,新旧元件可以混合使用。

RESISTANCE VS.Element Temperatuer for Yandi Super MS17 and MS18 Elements

The resistivity of elemenet rapidly rises along with the temperature rises, under normal operating conditions, generally the element resistance does’t change with the application time changing. So the old and new elements can be used together.

2.表面负荷 Surface load

根据炉子的结构、气氛和温度正确地选择元件的表面负荷是达到最好元件寿命的关键。右图示出了元件辐射在不受阻碍情况下的炉温、元件温度与表面负荷间的关系,阴影部分为常用的表面负荷-温度范围。

The key factor to the optimum service life of the element is to select the surface load of the element correctly cccording to the furnace consteuction, atmosphere and temperature. Right figure shows the relation between the furnace temperature, the element temperature and the element surface load under the condition that element radiation isn’t obstructed. The shadow part in the figure shows the surface load-temperature range in common use. The figure still shows the reference current.

推荐的表面负荷 Recommend surface load:

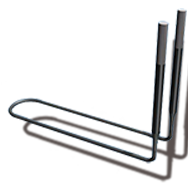

二硅化钼电热元件的安装 Installation of elements

1.垂直悬挂Vertically hanging

二硅化钼电热元件常温下脆性很大,高温时又有可塑性。所以U型元件的最好安装方法是垂直悬挂。通过固定夹将元件悬挂在炉顶上。这样安装的目的就是避免将机械应力加到元件发热端上,否则容易引起元件断裂。

Under normal temperature,Mosi,element is very brittle,while under high temperature it is plasticity.So,the better way for installation of the U Shape element is to hang it vertically to the furnace top by the element holder.Such way is to avoid putting the mechanical stress directly to the element heat-generating end,otherwise,the element will easily be broken.

2.固定夹 Element holder

整个元件的重量都是由固定夹承担,元件的位置也由它决定。因此,必须仔细安装,保证元件垂直悬挂。为避免局部过热,元件下端圆锥部分一定要伸到炉膛内。

The element holder supports the whole weight of the element and the position of the element is also determined by it.Therefore,it must be installed carefully to assure that the element is vertically hung.In order to prevent the element form being over heated locally,the taper part of the element lower end must put into the furnace chamber.

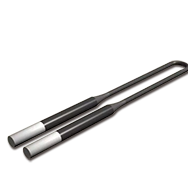

3.连接带Connection strap

接触元件的连接导线采用铝编织带或多层铝箔。外面的夹子只起夹紧作用,不用来导电。导线的末端与母线连接。为了避免应力传到元件上,导线长度应略大于元件和母线间的直线距离。

安装元件时夹头上的螺丝不要一次拧的太紧,待元件升到高温时再次拧紧,因为这时元件有一定可塑性不易折断。夹头部分温度一般不要高于200℃。因此,夹头导线与元件接触电压应降低0.1V。为避免辐射热传到夹头,夹头下端和穿砖上面的距离不应小于50mm。为了避免损坏,一般直径6/12mm元件不能长期使用170A,直径9/18mm元件不能长期使用300A。

The connection starp is made of aluminum braid strap or multi-layer aluminum foil.The outside clamp isn’t used for electrical conduction.The end of strap contacts bus,and the length of strap should be a little larger than the linear distance between the element and bus.

When install the element, don’t fix the strap too much at one time, it can be tightened shen the element rises to high temperature, as the element has some plastic and isn’t easily broken. The temperature of the wrie clip generally should’t be higher than 200℃. Therefore, the contact voltage between the clip wire and element should be lowered to 0.1V. In order to avoid that the radiation heat is conducted to the clip, the distance betweenthe lower end of the clip and upper surface of the thourgh brick should not less then 50mm. Generally for Φ6/12 element,170A should not be used long time and for Φ9/18 element,300A shouldn’t be used for long time.

二硅化钼电热元件的附件Accessories of element

二硅化钼电热元件的标准附件包括元件固定夹和两条带有夹子的铝编织连接带。用于不同直径元件的

附件如下:

The nominal accessories of MoSi2 elements includethe element holder and 2 aluminum braid connecting straps.The accessories for different diameter elements are the following.null

二硅化钼炉子的操作Operation of MoSiz furnace

1.炉子的干燥Drying of the furnace

新砌筑或长期不用的炉子在使用前需要干燥。一般干燥温度为100-200℃,而元件长期在低温下使用将会引起低温氧化。小型炉子干燥时间短,几个小时对元件影响不大。大型炉子干燥时间长,需要注意。为了通风,最好将炉门打开,随着温度升高可以半开,到1000℃以上完全关闭炉门。

The new built furnace or the furnace that haven’t been used for a long time should be driedbefore operation. The drying temperature generally is 100-200℃. The element that has been used for a long period under low temperature will cause low-temperature oxidation. For the small-sized furnace, as its drying time is short, several hours will affect the element little, but for the large-sized one,as its drying is long, it should be dried carefully.You’d better open the furnace gate to make it ventilated. The gate may be half-opened with therising of temperature and fully closed when the temperature rises above 1000℃.

2.炉子的启动Starting of the furnace

如果炉子干燥好了或不需要干燥就可以启动升温,为了避免过大电流冲击而使电器设备过荷,应采用下列步骤起动:

If the furnace has been dried or needn’t to be dried, then it may be started to raise temperature. In order to avoid that it is impacted by over current and the electric device is overloaded, the following steps should be adapted:

3.元件的更换Re3placing of element

在操作过程中发现元件损坏应首先确定位置,同时准备好组合元件。然后将损坏的元件夹头导线与母线连接的螺丝松开,清理开陶瓷棉,连用穿砖一起拔出来,再将新组合元件从炉顶插入,连接好导线,堵好陶瓷棉即可升温。

If it is found that one element is damaged during operating, firstly, you should determine where it is, at the same time prepare a made up one. Then loosen the thread which links the lead wire of the damaged element and the bus, clear out the ceramic cotton and pull out the through-brick. Afterward, insert the new element from the furnace top, link the lead wire, block the gap with ceramic cotton and start to raise temperaturenull

二硅化钼电热元件参考数据 Reference data for Yandi Super heating elements

1、1800等级3/6mm的U型元件

1800 Grade U type 3/6mm elements

2、1800等级4/9mm的U型元件

1800 Grade U type 4/9mm elementsnull

3、1700等级6/12mm的U型元件1700Grade U type 6/12mm elements

4、1800等级6/12mm的U型元件1800Grade U type 6/12mm elements

5、1700等级9/18mm的U型元件1700Grade U type 9/18mm elements

6、1800等级9/18mm的U型元件1800Grade U type 9/18mm elements

7、1700等级6/12mm的W型元件1700Grade Wtype 6/12mm elements

8、1700等级9/18mm的W型元件1700Grade W type 9/18mm elements

下一篇: U型硅钼棒MS17/MS18

郑州焱帝高温炉业材料有限公司

郑州焱帝高温炉业材料有限公司

型硅碳棒元件.jpg)

型硅碳棒元件.jpg)

型硅碳棒元件.jpg)

型硅碳棒元件.jpg)

硅碳棒元件.jpg)

型硅碳棒元件.jpg)